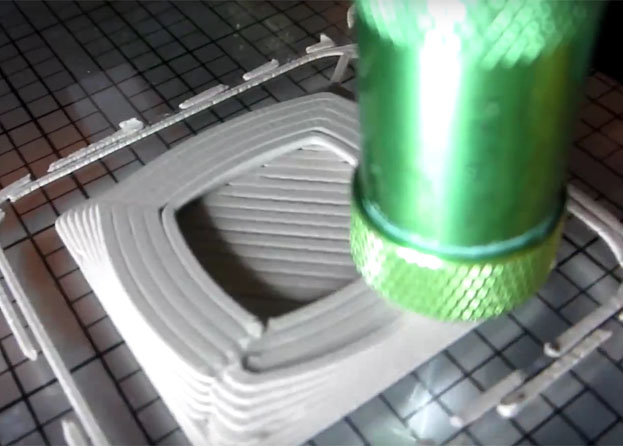

Atlanta-based Hyrel 3D has created a new extruder, which can print with Clay, Plasticine and even Play-Doh and RTV Silicone.

According to Daniel Hutchison of Hyrel 3D, this HYREL Emulsifiable Extruder (EMO1) has several advantages including:

- The cartridge-based system, which the user can load themselves.

- The ability to reuse the material. Thus it has a very low impact on the environment.

- Modular, using Hyrel 3D’s patent pending interchangeable head technology.

- Currently operated at room temperature, with no extra heat requirements, therefore no chance of getting burned.

- Perfect for schools – from Elementary up!

- Does not require a homogenized build environment (air ducts do not affect the prints).

- Safe and Non-toxic (clay, plasticine & Play-Doh).

- Variety of materials is virtually limitless

Watch the videos below to check it out:

1. 3D Printing with Air-Dry Modeling Clay

2. 3D Printing with Plasticine

3. 3D Printing with Play-Doh

The video for 3D printing with RTV Silicone will come soon. To make it easy to swap the extruder out on the HYREL 3D Printer to go back to ABS / PLA, Hyrel 3D has built in a CANBUS to handle all connects / disconnects to each printer. Watch the video below:

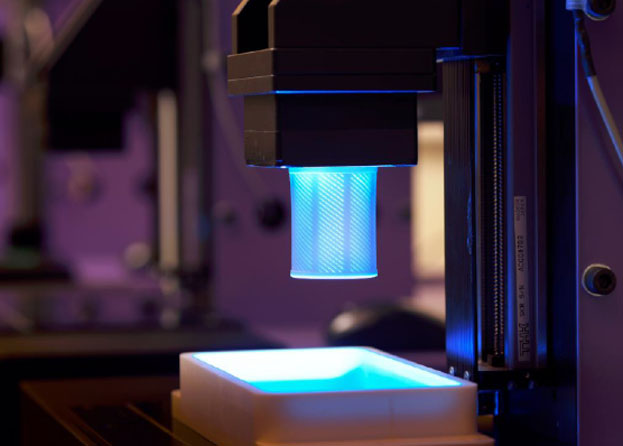

Hyrel 3D printer project successfully raised its funding goal in Sep 2012. Its latest 3D printers, Hyrel 3D printer Engines were showcased at this year’s Bay Area Maker Faire. The Hyrel 3D printer Engines feature a large 8″x8″x8″ (200x200x200mm) build area with multiple hot-swappable extruder head options. every HYREL Engine boasts a robust, all-metal chassis, powder-coated and anodized for durability.